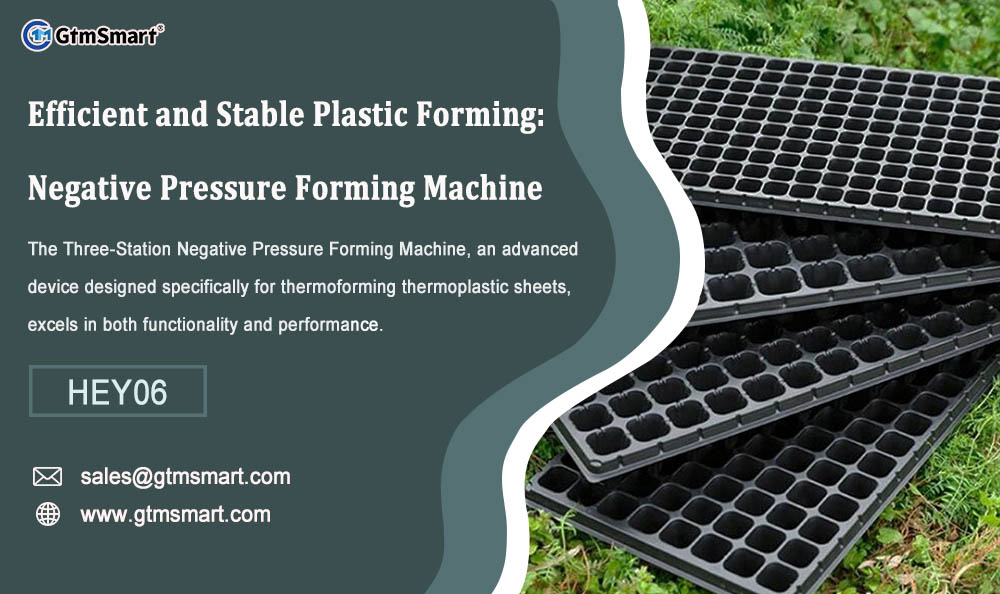

Efficient and Stable Plastic Forming: HEY06 Three-Station Negative Pressure Forming Machine

With the widespread application of plastic containers in agriculture, food packaging, and other fields, the demand for efficient and stable production equipment has been increasing. The HEY06 Three-Station Negative Pressure Forming Machine, an advanced device designed specifically for thermoforming thermoplastic sheets, excels in both functionality and performance. It is suitable for producing a variety of plastic products, including seed trays, fruit containers, and food containers.

Applications

The Hydroponic Seedling Tray Making Machine is mainly used for producing various plastic containers, such as seed trays, fruit containers, and food containers. Its wide range of applications allows it to meet the production needs of different types of plastic containers, making it an indispensable piece of equipment in the modern plastic processing industry.

Features

1. High-Efficiency Intelligent Control System: The Plastic Seedling Tray Making Machine integrates mechanical, pneumatic, and electrical systems, with each action program controlled by a PLC. The touch screen operation is simple and convenient. This design not only enhances the automation level of the equipment but also significantly reduces the difficulty of operation and labor costs.

2. Precise Servo Feeding System: The Negative Pressure Forming Machine is equipped with a servo feeding system, allowing for stepless adjustment of feeding length. This ensures a high-speed, accurate, and stable feeding process, greatly improving production efficiency. Such precise control makes the production process more flexible and suitable for manufacturing products of various specifications.

3. Advanced Dual-Phase Heating Technology: The upper and lower heaters adopt dual-phase heating, providing uniform heating and rapid temperature rise (from 0 to 400 degrees in just 3 minutes). Temperature control is precise (with fluctuations no more than 1 degree), and energy-saving effects are significant (approximately 15% energy savings). This heating method ensures uniform temperature distribution during forming, preventing thermal damage and improving product quality.

4. Fully Computerized Intelligent Temperature Control System: The electric heating furnace temperature control system uses fully computerized automatic compensation control, with digital input interfaces for partition control. It features high-precision fine-tuning, uniform temperature distribution, and strong stability, unaffected by external voltage fluctuations. This ensures the stability and consistency of the forming process.

User Experience and Feedback

Several companies using the Nursery Tray Machine have given it high praise. An agricultural company reported that since introducing the Plastic Seedling Tray Making Machine, the production efficiency of seed trays has increased, and the product qualification rate has significantly improved. Another food packaging company noted that the high degree of automation in the HEY06 greatly reduced the complexity and error rate of manual operations, making the production line run more smoothly and reducing production costs.

These user feedbacks not only demonstrate the excellent performance of the HEY06 but also highlight its tremendous value in practical applications. Users have found that the machine not only improves production efficiency but also significantly enhances product quality, further strengthening their competitiveness in the market.

Conclusion

The Fruit Container Forming Machine Three-Station Negative Pressure Forming Machine, with its outstanding design and high production efficiency, showcases significant advantages in the plastic container production field. Its innovative integration of mechanical, pneumatic, and electrical systems enhances the automation level while ensuring operational simplicity and production stability. Whether in the production of agricultural seed trays or food and fruit containers, the Negative Pressure Forming Machine is a reliable and high-quality piece of equipment that provides strong support for the development of the plastic processing industry.

By thoroughly understanding the various functions and advantages of the Negative Pressure Forming Machine, it is evident that it holds an important position in plastic container production. In the future, with continuous technological advancements and growing demand, advanced equipment like the Nursery Tray Making Machine is expected to find broader applications, driving the industry to new heights.